Design, supply and commissioning of Modular Concentrating

Complexes (MCC) for the enrichment of coal and anthracites.

There are 16 working MCC in Ukraine.

Installation of MCC modules.

Installation of MCC modules.

Modernization of water –and- sludge schemes of existing Concentrating Mills

(CM).

Supply of equipment for mechanical dewatering of concentrate for existing CM.

Design, implementation, installation and commissioning of highly efficient equipment

for mechanical dewatering anthracite concentrate. Replacement thermal drying

highly effective equipment.

An Area of industrial and commercial activity of the «IEC» RESEARCH AND PRODUCTION

CENTER, Ltd. is:

- The introduction of Modular Concentrating Complexes (hereinafter - the MCC)

and the schemes of deep concentration (up to 0.0 mm) of minerals and technogenic materials;

- The development of technology solutions for the modernization of existing Concentrating

Mills

- Development of technical solutions for the modernization of Concentrating Equpment;

- Production, supply and servicing of Concentrating Equipment.

The «IEC» RESEARCH AND PRODUCTION CENTER, Ltd bases its activities on

practical scientific research institutions (in particular - “Gipromashugleobogashchenie”

and “UkrNIIugleobogashchenie”, Ukraine), and is involved in solving production and

technical problems of the Customer.

As a part of our Company are functioning:

- Design Bureau for technical and technological developments MCC ;

- Experimental production of the latest Concentrated Equipment, including Filtering Centrifuges , Besieger Centrifuges,

high screening, magnetic and electromagnetic separators, rack thickeners, belt filter presses, etc.;

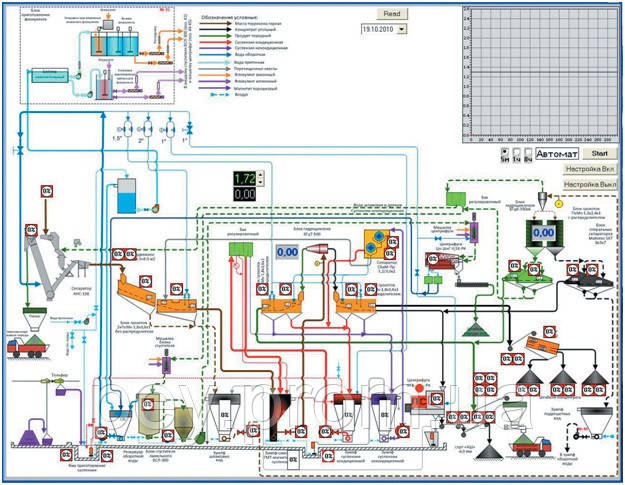

- Experimental production of systems of automatic technological processes control the MCC ;

- Service of control of operation MCC .

«IEC» RESEARCH AND PRODUCTION CENTER, Ltd specialists’ experience on inculcation of the MCC is more than

10 years, which justify their perspectives on the engineering services of the Commonwealth of Independent States countries,

including:

- Enrichment technology embedded in the MCC, is relevant, economically promising and has minimal risks to the

intended result;

- MCC technology allows you to quickly adjust the qualitative and quantitative measures of output of enrichment

based on the current market conditions.

The underlying technology IOC:

- Deep gravity-magnetic enrichment unclassified source material in heavy medium without prior and subsequent

grinding.

- MCC provides efficient separation of the source with the maximum recovery of valuable fractions, as on the density

(heavy product - lightweight product) as on the magnetic parameters (a strongly magnetic product – a weakly magnetic

product - a non-magnetic product).

Maximum economical effect of MCC:

- The application of efficient processing conversion (gravity concentration in a heavy-medium and short-cone water

hydrocyclones, gravity concentration in spiral separators; high-gradient enrichment in rotary electromagnetic separators,

thickening of the clay fraction in the lamella thickeners, etc.);

- The use of modern automatic control of the enrichment process

- Accommodation MCC on board the hoarders;

- Closed scheme of regeneration of magnetite weighting agent;

- Closed scheme of motion of the intermediate product;

- A closed water-sludge separation scheme with recycled water and elimination of the clay fraction of a transportable

consistency from an enriching scheme.

The performance advantages of the MCC:

- The rejection of the use of capital facilities and maintenance of the MCC in a light

metal pavilion equipped with a beam cranes lifting capacity up to 5 tons;

- Low cost of capital construction and the short period of construction works (MCC

assembled from transportable modules, enrichment and support equipment is mounted in

a module that provides rapid replacement of assemblies and components);

- Optimal compactness placement of an equipment (MCC took 5 times smaller in

volume than

An ordinary enterprise, comparable in performance and quality of products of Concentrating);

- Minimum number of maintenance staff in the three (3) members: one (1) of Saur

and two (2) fitters- electricians;

- Small period of construction works (the period of the project to the MCC assembly equipment at the customer site

is 3 - 6 months);

- High mobility (moving between the MCC to a new place of operation is less than 60 shifts);

- High efficiency of investment (total investment below an order of magnitude compared to conventional company);

- Supporting structures MCC associated with building design to the main hall;

- The possibility of making of the MCC using as the supporting structures of marine cargo containers;

«IEC» RESEARCH AND PRODUCTION CENTER, Ltd first developed and introduced

to the MCC process heavy-average enrichment of unclassified rock slagheap

(without pre- desliming) with deep of concentration to 0.1 mm and a separate recovery

of magnetite weighting agent.

The advantage of this method is:

- In the scheme of enrichment an excessive sliming is eliminated;

- Magnetite Weight agent of concentrate and rock paths is washed separately, so

gets low-ash concentrate of class size -1.0 + 0.1 mm.

It has received a concentrate on the MCC with grade size -1.0 +0,1 mm following

qualities:

- Ash content of a concentrate is 0.1 mm -1.0 +0.1 mm Ak = 12%;

- Ash content of rocks is -1.0 0.1 mm Ar = 90%.

Control cabinet MCC

Complete automation of processes

Implementation stages of the MCC:

Technical expertise and optimization technology of enrichment:

- A significant reduction in the cost of the final product, including reducing the

cost of expensive production stages;

- Optimization of the entire set of parameters related to the operation of the technological

process, the individual process stages and individual equipment;

- Testing in the laboratory mineral processing equipment key elements of the MCC to assess the correctness of industrial

equipment sizing has the MCC, the effectiveness of operating costs, the level of productivity, profitability commodity

product, environmental risks, etc.

Develop business implementation project MCC:

- Development of technical design and feasibility study for the MCC;

- Development of design documentation of the latest Concentrating Equipment which is used in the MCC;

- Development of regulatory and normative design documentation for MCC.

Financing business project implementation of MCC

- Assistance to the Customer in the business project financing from internal or external sources;

-Analysis of the effectiveness of customer’s existing technology, automation of technology process and evaluation of

maintenance of Customer’s equipment.

Technology guarantees and after-sales service

(including spare parts and consumable quick- wear and tear items) are provided by the Supplier for the all MCC

equipment, whether the equipment is manufactured by «IEC» RESEARCH AND PRODUCTION CENTER, Ltd, or a third

party.

Maintenance of the MCC:

- Installation supervision and start-up activities;

- Current and planned equipment maintenance of the MCC (including adjustment, mechanical and process audit);

- Training of staff;

- Emergency repairs.

The use of high-tech equipment designed by «IEC» RESEARCH AND PRODUCTION CENTER, Ltd, which has been

tested as in the certification system of Ukraine, as by exploitation of on-site customer, led to the following indicators:

Examples of the most effective schemes enrichment using MCC capacity up to 100 tons / hour:

Enrichment of raw coal and tailings (slagheap Ad ≤ 85,0%) cells. cr-minute -50.0 +0.0 mm with a depth of source

material enrichment ≥ 1,0 mm with the release of 2 products:

- Concentrate Ad = 7,0%, with the humidity within the requirements of ГОСТ to the class size and containing 0.5%

of the heavy fraction;

- Rocks Ad = 85,0% with 0.5% of the light fraction.

Enrichment of coal sludge cells. cr-minute

-1.0 +0.0 mm Ad = 45 ÷ 50% with the release of 4 products:

- Concentrate Ad = 9,0% to 12,0% humidity, suitable for coking;

- Rocks Ad ≥ 75,0% from non-regulated humidity;

- Gali cells. cr-minute 1.0 mm with unregulated humidity;

- Clay cells. cr-ti ≥ 0,05 mm transportable consistency.

Enrichment of ash materials (ZSHM) energy-generating companies with the release of these liquid products:

- Underburning coal (“bead” and fine);

- Magnetite (“shot” and fine);

- Mullah enriched fine;

- Cenospheres;

- Ferrosilicon;

- The product of rare metal (including Ge-containing).

All equipment has a resolution (Dozvil) on the application at all of the Concentrating Mills of Ukraine. Due to the

large volume of «IEC» RESEARCH AND PRODUCTION CENTER, Ltd provides a large stock of spare quick-wear parts and

spare parts with long delivery.

Director D.Kvitkovsky

Our company has organized in 1999 and is engaged in the manufacture and supply

of mining equipment and spare parts in the Ukraine, Russia, Belarus, Kazakhstan

and abroad.

Engineering Center of the Company de-signs screens and magnetic separators

of all sizes, in the case of the working envi-ronment of the customer. Considering the

needs and mechanics’ technical solutions , who run our equip-ment, we are able to reduce

your costs for repair and setting up our equipment, energy vehicles, and at the

same time to increase the performance and service life.

•Riddles (modernized and serial);

•Modernized riddles: similar to the foreign manufacturers such as, «Siebtechnik»,

«Metso», «Schenck», «Sandvik», «Ludowi-ci»;

•Lifting Electromagnets;

•Suspended Separators of iron;

•Sheave Separators of iron;

•Self-unloading Suspended Separators of iron;

•Arc Sieves, Arc Sieves vibratory;

•Hydrocyclones (lined with silicon car-bide);

•Vibratory Feeders (instead of feeders ЖВЕм);

•Swing feeders;

•Lamellate feeders;

•Inclined Dehydrating bucket Elevators;

•Electromagnetic separators;

•Drum Electromagnetic Separators;

•Roll crushers;

•Test-division Machinery;

•Pendulum samplers, Gap Samplers, Bucket Samplers, Elevator Samplers;

•Centrifuges;

•Stationary conveyor belts Type;

•Movable conveyor belts Type;

•Scrapery Conveyors and Scraper Chains Type;

•Сable Pushers;

•Shunting devices;

•Pumps Type;

•Screening surfaces (Screens);

•Metal (perforated, braided, fissural ), rubber, polyurethane;

•Spare parts for the aforementioned equipment.

Інформація для замовлення

- Ціна: Ціну уточнюйте